- Home

- >

- Knowledge

Serving with Expertise

Every package represents our holistic knowledge

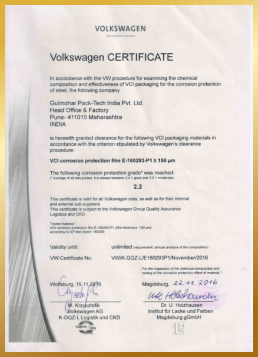

Volkswagen Certificate

1) This certificate, awarded by Volkswagen AG, recognizes Gulmohar Pack-Tech’s use of VCI (volatile corrosion inhibitors) packaging materials that provide effective corrosion protection for steel.

2) The certification ensures that Gulmohar’s VCI packaging meets Volkswagen’s rigorous chemical composition and effectiveness criteria, making Gulmohar a trusted supplier for Volkswagen’s global operations.

3) With this certification, Gulmohar showcases its alignment with industry best practices and quality standards, reinforcing its reputation as a reliable partner for automotive and industrial sectors.

BFSV R+D Project Certificate

1) This certificate stems from a testing project conducted by the BFSV Institute, which evaluated Gulmohar’s VCI film according to the TL 8135-0043 standard for corrosion protection effect.

2) The test results confirmed that Gulmohar’s VCI film meets grade 3 for corrosion protection, reflecting a high level of efficacy and adherence to established industry standards.

3) This certificate emphasizes Gulmohar’s commitment to rigorous research and development, as well as its ability to provide reliable and protective packaging solutions that safeguard products and materials.

Features of Intermodal Containers

The first line of defense for your goods

Durable Construction

Standard shipping containers are made of strong, corrosion-resistant steel, ensuring durability and longevity. These containers are designed to withstand harsh environmental conditions, including exposure to saltwater, moisture, and temperature fluctuations.

Standardized Sizes

Shipping containers come in standardized sizes, primarily 20-foot and 40-foot lengths, allowing for efficient stacking, storage, and transport. This standardization facilitates seamless loading and unloading across different transportation modes, such as ships, trains, and trucks.

Security Features

Containers are equipped with secure locking mechanisms to protect cargo from theft and tampering during transit and storage. Additional security options, such as padlocks and tamper-evident seals, can be implemented for enhanced protection.

Ventilation and Insulation

Containers are designed with ventilation systems to prevent the buildup of moisture and heat, which can damage cargo. Optional insulation features can be added to regulate temperature and protect sensitive cargo from extreme heat or cold.

Modular and Versatility

Standard shipping containers can be easily modified and customized for various uses, such as adding doors, windows, or shelving. Their modular design allows for versatile applications beyond cargo transport, such as temporary storage, offices, and even housing.

Sustainability

Containers can be repurposed or recycled at the end of their lifespan, contributing to sustainability efforts. Using shipping containers for alternative purposes, such as storage and housing, can reduce waste and extend their lifecycle.

- Container rain, also known as container sweat or container condensation, refers to the accumulation of moisture inside shipping containers during transit, especially when goods are transported by sea.

- This moisture buildup occurs due to temperature differences between the inside and outside of the container, as well as changes in humidity levels. When warm air contacts the colder surfaces of the container walls, ceiling, or cargo, condensation forms, resulting in water droplets.

- Container rain can damage goods, causing rust, mold, or mildew, particularly in sensitive items such as electronics, textiles, or food products.

- To prevent container rain, proper ventilation, insulation, and moisture-absorbing materials are used in packaging and container design.

- ISPM-15 stands for International Standards for Phytosanitary Measures No. 15. This international regulation was developed by the International Plant Protection Convention (IPPC) to address the spread of pests and diseases through the international movement of wood packaging materials (WPM).

- ISPM-15 requires that all wood packaging materials used in international trade, such as pallets, crates, and dunnage, be treated using approved methods to kill potential pests and their larvae. The most common treatment methods are heat treatment (HT) and fumigation with methyl bromide (MB).

- Wood packaging materials that comply with ISPM-15 regulations are marked with a specific stamp or mark, indicating they have been treated according to the standard.

- Compliance with ISPM-15 is mandatory for international trade in many countries to prevent the spread of pests and protect global plant health.

- Material Selection: Choosing renewable, recyclable, biodegradable, or compostable materials to reduce environmental impact. This may include using recycled content or plant-based plastics.

- Resource Efficiency: Optimizing packaging design to minimize material usage and waste generation while maintaining product protection and integrity.

- Energy Efficiency: Using energy-efficient manufacturing processes and transportation methods to reduce carbon emissions and energy consumption.

- Lifecycle Considerations: Assessing the environmental impact of packaging throughout its lifecycle, including production, distribution, use, and end-of-life disposal or recycling.

- Waste Reduction: Designing packaging to be reusable, refillable, or easily recyclable to minimize waste and promote a circular economy.

- Biodegradability and Compostability: Selecting materials that can naturally biodegrade or compost at the end of their lifecycle, reducing the burden on landfills.

- Supply Chain Transparency: Ensuring transparency and accountability throughout the supply chain to promote ethical sourcing practices and minimize negative social and environmental impacts.

- Several chemicals have been banned or restricted in desiccants due to their harmful effects on human health and

the environment. These include:

- Silica Gel with Cobalt Chloride: Cobalt chloride, a moisture indicator commonly used in blue silica gel desiccants, has been banned in many countries due to its classification as a carcinogen and its toxicity to aquatic organisms.

- Calcium Chloride (CaCl2) with Dimethyl Fumarate (DMF): Dimethyl fumarate, often used as an anti-mold agent in desiccants, has been banned in the European Union due to its potential to cause severe allergic reactions in humans.

- Activated Carbon with Trichloroethylene (TCE): Trichloroethylene, a solvent sometimes used in activated carbon desiccants, has been banned or restricted in many countries due to its classification as a carcinogen and its negative impact on the environment.

- Certain Pesticides and Insecticides: Desiccants may contain pesticides or insecticides to prevent the growth of mold, fungi, or insects. However, many of these chemicals have been banned or restricted due to their harmful effects on human health and the environment.

- Always check the ingredients and safety certifications of desiccants to ensure they comply with regulations and do not contain banned or restricted chemicals. Choosing desiccants that are certified as safe and environmentally friendly helps mitigate potential risks to health and the environment.

- The Forest Stewardship Council (FSC) is an international non-profit organization that promotes responsible forest management worldwide. The FSC offers a certification system that ensures forest products, such as wood and paper, are sourced from forests managed in an environmentally, socially, and economically responsible manner.

- The FSC certification process involves rigorous standards and criteria that address key issues such as forest conservation, biodiversity protection, indigenous rights, community engagement, and sustainable harvesting practices. Forest operations that meet these standards can be certified as FSC compliant, and products derived from these forests can bear the FSC label.

- Consumers can look for the FSC logo on wood and paper products to identify items that come from responsibly managed forests. Supporting FSC-certified products helps promote sustainable forestry practices, conservation efforts, and social responsibility within the forest products industry.